Avionic Repairs

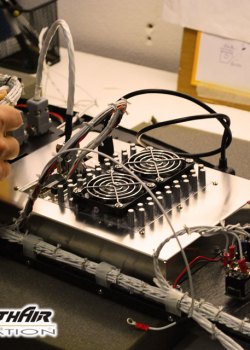

The NorthAir Aviation has a modern laboratory with avionics equipment professional, here are performed repair work and testing of the following products:

- Test and repair of apparti VHF Com and Nav, Transponder A / C / S, control audio, ELT 406 MHz and 121.50 of brands: Funke, Becker, Ack, Ps engineering, Kannad, Icom;

- Test and repair aeronautical Headphones with genuine parts of the brand: Bose, David Clark, Sennheiser and Lightspeed;

- Changing the method flat repair: Northair avaition handles repairs of Units’ certified Garmin with quickly switch apparatus failure with a new or refurbished equipment with equivalent certificate form 8130;

Training

Northair Aviation organizes courses and training activities for companies operating in the field of light, and not for professional pilots.

The objective of these courses is to provide professional information that have as their object the digital avionics glass panel.

The courses are often organized with the partnership of important figures in the world of aviation and avionics manufacturers direct. These events can be collective or, on request, individual

Contact us to learn more!

Consulting

Northair Aviation responds to every kind of problem, request and demand in the field of avionics for aircraft lightsport and experimental, all this to offer many services for the client.

Screen printing four-color panels High Definition

NorthAir Aviation provides the service of written and graphic realization of panels with an innovative technique for high-resolution, four-color printing.

Along with the printing service NorthAir Aviation also makes it the embodiment of the image file in DWG format that includes all the written signs of Warming / Caution and graphics grouping.

The whole ‘equipment needed to make prints on the panels is in the company, this element allows for a limited time of implementation and no minimum quantities of realization.

CAD design and CNC cutting of aluminum and composite

Thanks to cutting center with CNC NorthAir Aviation workspace 1400 x 600 mm, you can cut custom panels of aluminum or composite material of high dimension.

Our technical department realizes drawings and layout panels or structures customized avionics and makes a direct cut with the CNC machine on the farm. This process is extremely flexible and fast what ‘now we are to achieve the particular custom during the installation of avionics.

The CNC machine also allows you to create prototypes of special aluminum brackets or before going into production with final pieces.

Studio layout of panels in 3D

With mechanical design software, NorthAir Aviation realizes the study of new layout of panels according to customer needs, it has an ‘extensive library of 3D cockpit of the most popular aircraft models Experimental and Light Sport Aircraft.

With 3D simulation of the panel can be analyzed graphically in a careful and precise space and feasibility of hosting a new avionics of a particular aircraft.

These studies layouts offer the possibility for the customer to have a 3D simulation of the new cockpit and see how you will present the panel completed.